Editor: Saib Mate Tag nrho cov iav Railing

Hom iav rau Railings

1.Float iav (Pilkington txheej txheem)

Kev tsim khoom: Molten iav floated ntawm molten tin kom ua tiav cov tuab tuab.

Yam ntxwv:

Tsis-tempered, yooj yim structural zog.

Tsis tshua muaj siv nyob rau hauv railings yam tsis tau ua ntxiv.

2.Annealed iav

Txheej txheem: Ua kom txias qeeb hauv lub qhov cub lehr kom txo cov kev ntxhov siab sab hauv.

Kev txwv:

Yooj yim rau thermal / mechanical shock.

Txhaum qauv: Dangerous loj shards (tsis ua raws li cov qauv kev nyab xeeb)

3.Heat-Strengthened iav

Txheej txheem: Kub rau 650 ° C, txias me ntsis (2 × lub zog ntawm annealed).

Daim ntawv thov: Cov ntaub thaiv phab ntsa uas tsis tas yuav tsum muaj tempering.

Txhaum qauv: Cov khoom tawg loj dua li tempered (ib feem kev nyab xeeb)

4. Tempered iav

Txheej txheem: Ceev ceev quenching ntawm 700 ° C (4-5 × muaj zog tshaj annealed).

Ua raws li kev nyab xeeb:

Txhaum qauv: Granular fragments (EN 12150 / CPSC 1201 tau ntawv pov thawj). Yuav tsum tau rau freestanding balustrades.

Txaus ntshai: Spontaneous breakage vim impurities.

Kev daws: Ua kom sov so ntawm 290 ° C rau 2 teev kom tshem tawm NiS tsis ruaj khov.

5.Glazing Systems sib piv

| Qhov system | Qhov zoo | Kev txwv |

| Dej Glaze | - Superior huab cua tsis kam | - Portland cement puas PVB |

| (Gypsum / Silicone) | - Zoo tagnrho rau kev teeb tsa nkhaus | - 24-48 teev kho lub sijhawm |

| Qhuav Glaze | - 80% kev txhim kho sai dua | - Cov khoom siv ntau dua |

| (Gasket / Clamp) | - Tsis xav tau curing | - Txwv rau kev khiav ncaj |

6. Cov khoom thauj khoom

Linear LoadCeev: 50 plf (0.73 kN / m)

Concentrated Load: 200 lbs (0.89 kN) nyob rau sab saum toj ntug.

Laminated iav Mandate

Tom qab 2015 IBC: Tag nrho cov railings yuav tsum tau laminated iav (≥2 plies, sib npaug thickness).

Kev zam: Monolithic tempered iav tso cai tsuas yog tias tsis muaj taug kev hauv qab no

7.Top Rail Kev zam

Tso cai yog tias:

Laminated iav dhau qhov kev xeem thauj khoom (ASCE 7).

Pom zoo los ntawm lub tuam tsev hauv zos (2018 IBC tshem tawm qhov yuav tsum tau ua).

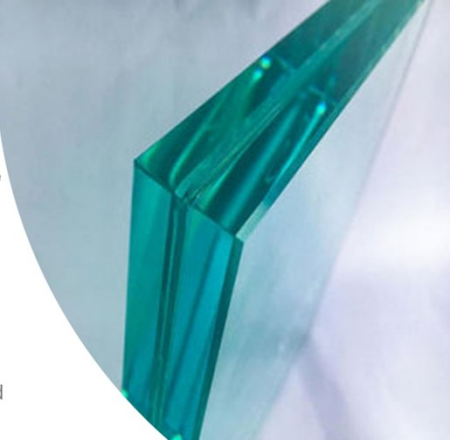

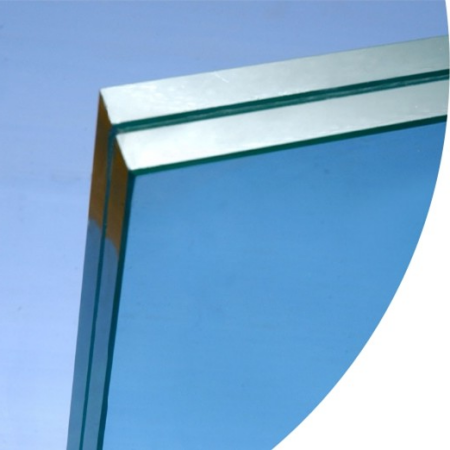

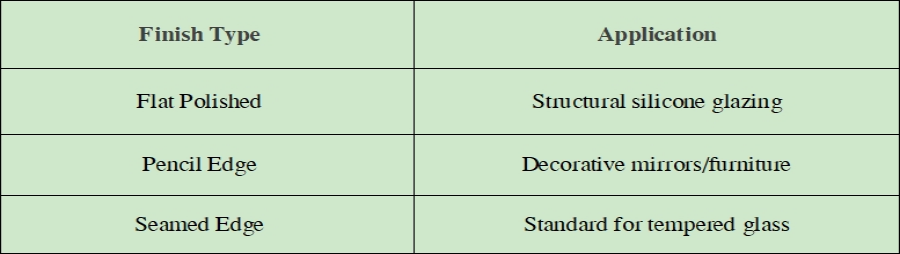

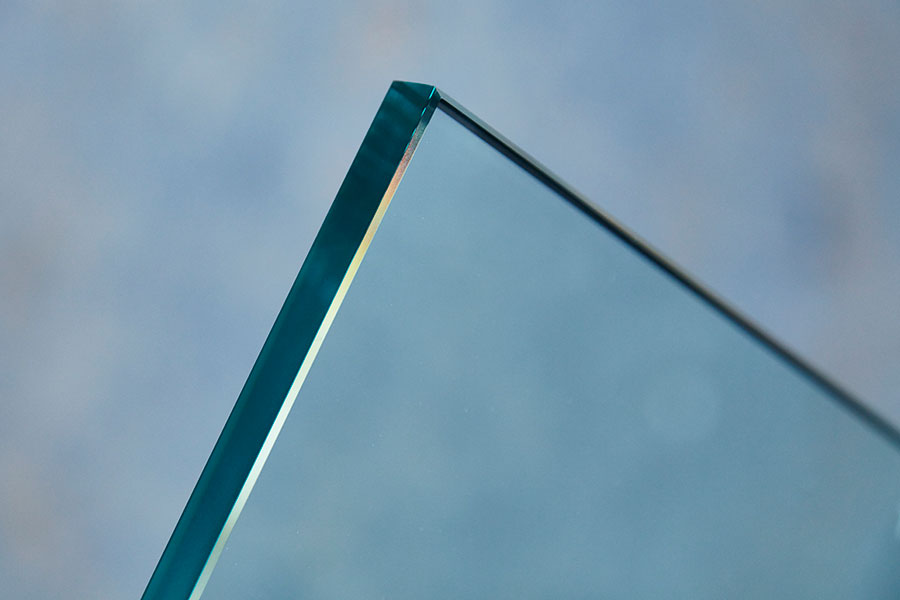

Ntug Finishes & Durability

Kev txhawj xeeb: Ionoplast interlayers ua tau zoo tshaj PVB hauv cov av noo tsis kam.

8.Cov Hom Failure

Nelophobia Triggers:

Nickel sulfide inclusions (cov cua sov so kom txo tau 95%).

Kev ua raws ntug tsis raug (ASTM C1172 ua raws qhov tseem ceeb).

9.Cua-Borne Debris Zones

Cov cua daj cua dub hauv cheeb tsam suav nrog Gulf of Mexico, Atlantic coastline, Hawaii • Balusters thiab in-filled panels yuav tsum tau laminated iav • iav txhawb kev tsheb nqaj hlau sab saum toj - Lub rooj sib dhos yuav tsum tau sim raws li qhov yuav tsum tau muaj - Cov tsheb ciav hlau sab saum toj yuav tsum nyob hauv qhov chaw tom qab muaj kev cuam tshuam

10. Cov lus xaus

Railing systems tsim nrog laminated iav muab kev nyab xeeb thiab iav tuav tom qab tawg • Ionoplast interlayers muaj zog dua, deflect tsawg dua, thiab muab kev ua tau zoo dua tom qab iav tawg hauv cov railings tsawg kawg nkaus • Lub tsev code yuav tsum tau rau railings pub laminated iav thiab, qee zaum, yuav tsum tau laminated iav rau missile tej yam thiab cov qauv iav tshuab • Sealant cov ntsiab lus tshwj xeeb yuav tsum tau.

Post lub sij hawm: Jun-25-2025